Fiber Laser Marking

The beam emitted by the laser generator is focused by the optical path system into a laser beam of high power density. The beam is irradiated onto the surface of the part to bring the part to a melting point or boiling point, while the high-pressure gas coaxial with the beam blows away the molten or vaporized material. As the beam moves relative to the part, the material is slit finally, thereby achieving the purpose of cutting.

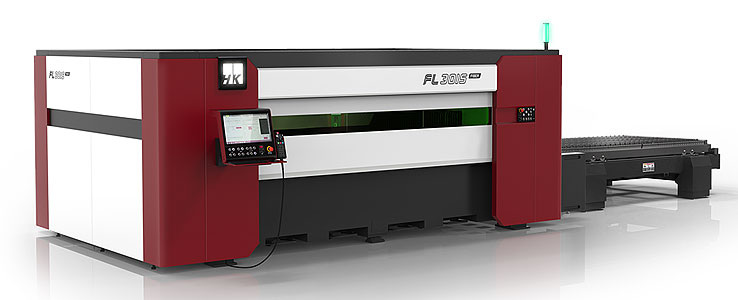

Laser cutting machines can be classified as fiber laser machines or CO2 laser machines depending on their laser sources.